24/7 MAINTENANCE

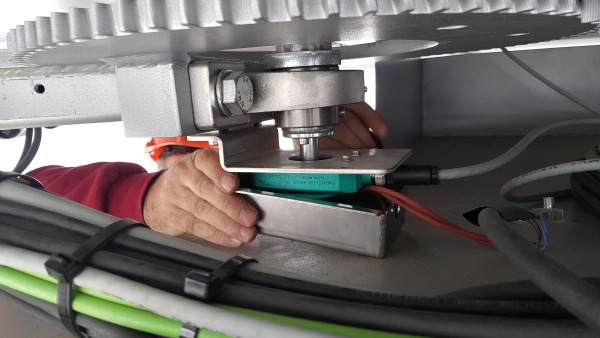

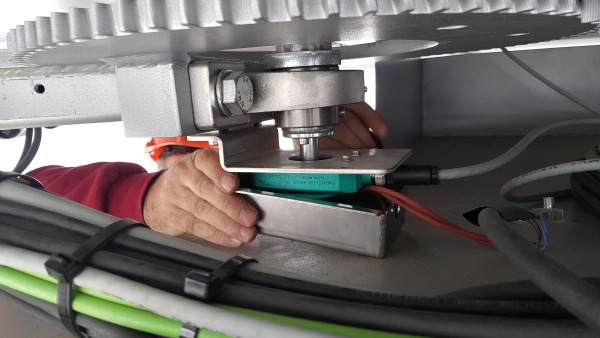

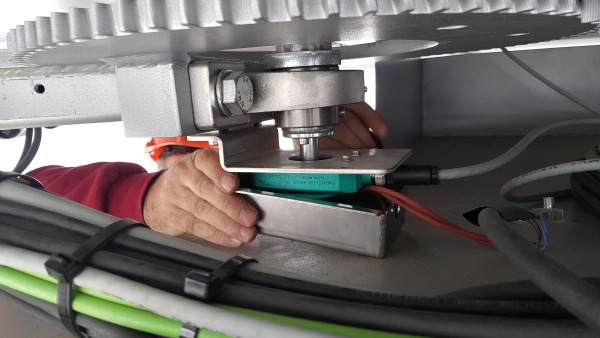

Maintenance is the backbone for the operations to keep passenger boarding bridges in ideal conditions, and we are reaching all main components easily to allow preservation tasks to be carried out thanks to our direct access system.

CUSTOMIZED PRODUCT LINES

We are producing and designing our passenger boarding bridges while regarding the airport’s specific requirements by choosing the right size of configuration, drive system, elevation type, body configure, effective air conditioning system, and other design options, such as steel or glass tunnels, rain drains, etc.

LOW OPERATION COST

Our engineers are designing the elevation and translation system consideri̇ng maximum energy efficiency and they are also preparing pbbs taking into account the most efficient way to deliver preconditioned air and electricity to the stationed aircraft to reduce energy consumption.

SAFE, QUICK AND SIMPLE

For a reliable safety system, ubs airport systems using a cabin control system on their pbbs. in addition to this, using multiple sensors and a fully automated docking system provides safe, simple, and quick docking operations without any risk for the aircraft or operator at the apron.

HIGHER PRODUCT QUALITY AND RELIABILITY

UBS airport systems pbbs have strong, durable, and lightweight steel to form the safest and high-quality products. additionally, all materials have a guarantee to provide excellent endurance.

SAFETY AND COMFORT FOR PASSENGERS

As UBS Airport Systems, we believe that when passengers enter our Passenger Boarding Bridges, their journeys begin. Therefore, technical solutions should be efficient and design should be appealing. In addition incorporating sides such as acoustic and thermal insulation, using natural lighting, efficient air-conditioning system, and convenient ramp slope, non-slip flooring, all of these qualifications make a difference to a passenger’s viewpoint of the service provided by an airport or airline.